Intralogistics

OUR SOLUTIONS

Intralogistics solutions

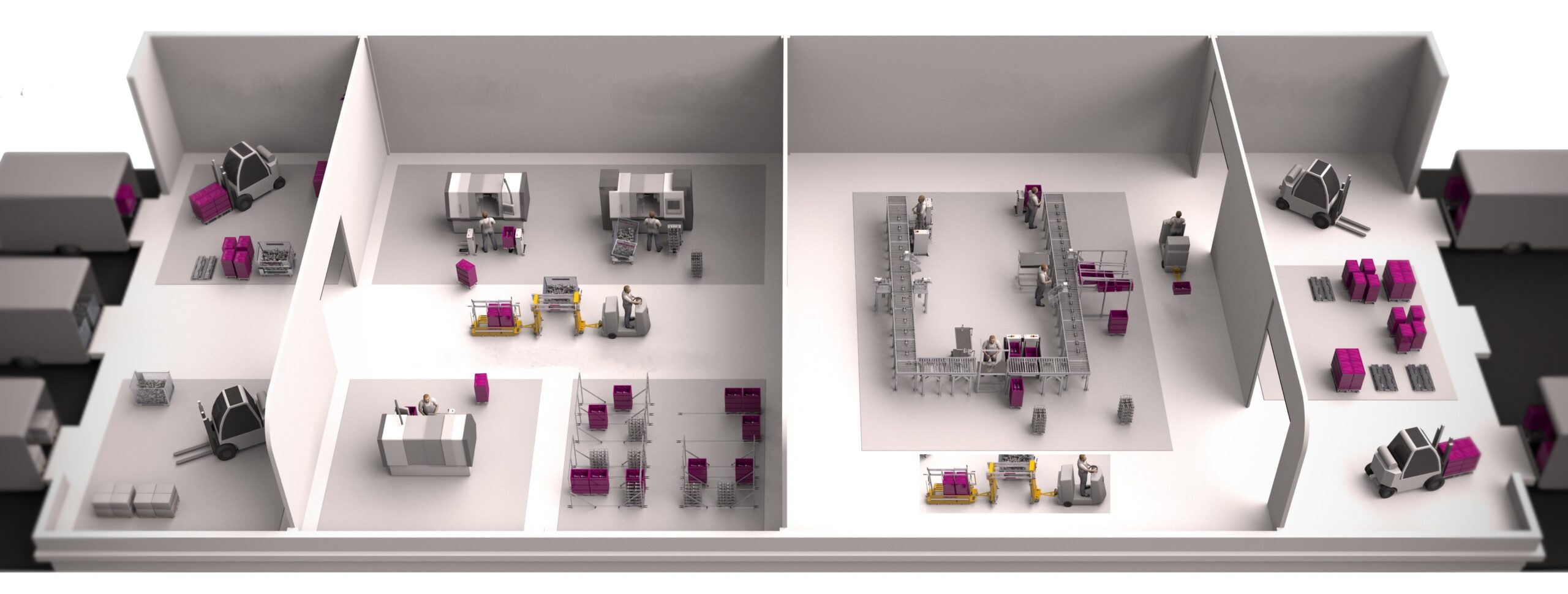

Efficient intralogistics reduces inventory, handling and internal transport costs. Our solutions support Lean manufacturing principles through improved space optimization, shorter manufacturing process times, improved worker safety without the use of forklifts in the production space.

Key industry trends such as robotics and automation, the anticipation made possible by IoT and data analytics, and the increased demand for sustainable solutions will shape the direction of intralogistics across all industries.

Comprehensive solutions for your plant

In Automationstechnik, we develop solutions that optimize intralogistics and production ergonomics in manufacturing plants based on the offerings of our partners:

Bloksma

The manufacturer of workstation lifts, trolleys, workpiece carriers, supermarkets, and other specialized logistic units. These solutions make a maximum contribution to improving the efficiency of production processes.

K.Hartwall

The producer of logistic solutions, such as workpiece carriers with adaptive pallets, logistic trains, and mobile AGV/AMR robots. These solutions, skillfully used in production processes maximize their efficiency.

AUTOMATIONSTECHNIK

Visual Management

As the exclusive distributor in Poland, we offer solutions from the German company Orgatex – a manufacturer of horizontal and vertical signage that is part of Visual Management.

Effective Visual Management of production and warehouse areas leads to improved safety, organization, and process optimization. It should comply with applicable regulations and be logically integrated with the layout of production and warehouse lines.

Defining communication pathways is a fundamental element in reducing the risk of accidents. Adhering to rules for movement in designated zones is facilitated by individual color coding, tailored to procedures and company standards.

Similar principles apply to vertical markings, such as information frames, labels on Kanban cards, etc. These markings describe workstations, individual stages of the production process, material flow, and visualize warehouse management.

Just like with horizontal signage, vertical markings play a crucial role in creating a visually organized and efficient workspace. They provide clear information about the status of workstations, guide employees through different process stages, and help optimize material flow within the production facility. This visual communication contributes to enhanced safety, better organization, and increased overall efficiency in both production and warehouse management.

Continuous improvement

– KAIZEN

In Visual Management, the principle of continuous improvement, known as KAIZEN, is crucial. Products for creating visual management should possess durability suitable for production environments and flexibility that allows for easy refinement of implemented solutions. The comprehensiveness of these solutions is also significant, as it enables visual standardization across the entire facility at every organizational level.

Interest in visual management products is often motivated not only by occupational health and safety considerations, employee comfort, or the need to increase efficiency or better organize the production area. Appropriate Visual Management indicates a high level of production culture, serves as an important parameter during audits, and is positively perceived during visits by potential clients.

Why it is worth investing in intralogistics?

- Optimization of warehouse, transportation, and inventory management processes enables controlling the company’s resources and reacting faster to market changes.

- Improving efficiency by faster movement of goods within the company – shortening order fulfillment times, increasing the company’s production and sales capabilities.

- Enhancing inventory control, resulting in reducing the risk of overstocking or stockouts.

- Improving employee safety and reducing absences due to injuries.

- Optimizing the use of production space to achieve better operational results, cost reduction, and increased market competitiveness.

- Shortening order fulfillment time, leading to increased competitiveness and higher customer satisfaction.

- Minimizing transportation costs through route optimization, packaging, and product storage optimization.

- Savings resulting from reduced employment needs and mitigating the risk of errors.

- Adaptation to rapidly changing market conditions by responding faster to changes in demand, market trends, and potential crises.

AUTOMATIONSTECHNIK

Optimize your processes with Automationstechnik

We have been improving and optimizing production processes for 25 years. Check why it is worth working with us.

Quality

The ISO 9001:2015 certificate confirms the quality of the solutions provided

Experience

Over 25 years of experience in the design and construction of machines and assembly lines

Knowledge

We identify and solve problems by ensuring the required KPIs in production.

Complexity

We accompany the client from the first sketch to implementation and implementation of solutions.

CONTACT

Need more information?

Get in touch with our Team!

Leave us your contact details, and our specialists will answer all your questions.

Phone

Address

ul. Rzemieślnicza 20A, 30-363 Kraków